Not a Fair Fight - CUBE 40 mount vs Top Competitor

, by Steve Coulter, 1 min reading time

, by Steve Coulter, 1 min reading time

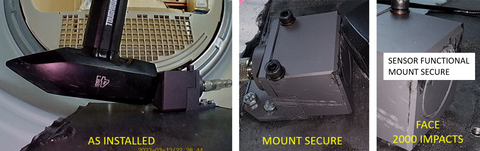

We tested the CUBE 40 Sensor Mount (Adapts 30mm sensors to the 40mm cubic format) against several top competitor's sensors in the 40mm cubic format

Below is a highlight between the top performing competitive sensor and the CUBE 40 with 30mm WSI sensor: Both sensors mounted to the same bolt pattern in a steel baseplate with steel screws. 4lb steel sledgehammer.

We ran each sensor through the impact process to find out 1) how many strikes until failure and 2) the cause of failure.

As you can see in the center picture above, this competitive sensor broke at the mount after 313 impacts. This was the most durable competitive sensor we tested, and though broken, it still seemed to operate. Other competitive cubic sensors failed similarly between 1-20 strikes.

CUBE 40 (above) as installed and post test inspection: After 2000 impacts we stopped the test on Weld Dynamix CUBE40 to evaluate - the mount easily survived the impact, and held the sensor securely in position. The sensor was observed to be 100% functional and ready for more action. Aside from scratches, no serious degradation to the mount face or sensor was observed.

The CUBE 40 mount is currently available in 2 formats: #WMT-30MM-FXXH GF Nylon Nose with machined steel base (as tested) or #WMT-30MM-FFXH Machined Steel Nose & Base, for applications utilizing continously as a hard stop.